The development speed of CNC machine tools in China is very rapid.

In recent years, the scale of China's CNC machine tool industry has continued to expand. It is expected that the scale of my country's CNC machine tool industry will reach 409 billion yuan in 2023, a year-on-year increase of 6.9%. This growth trend shows that China's CNC machine tool industry is developing very fast, and the market share of domestic high-end CNC machine tools has steadily increased, showing that China's competitiveness and market influence in this field are constantly increasing1.

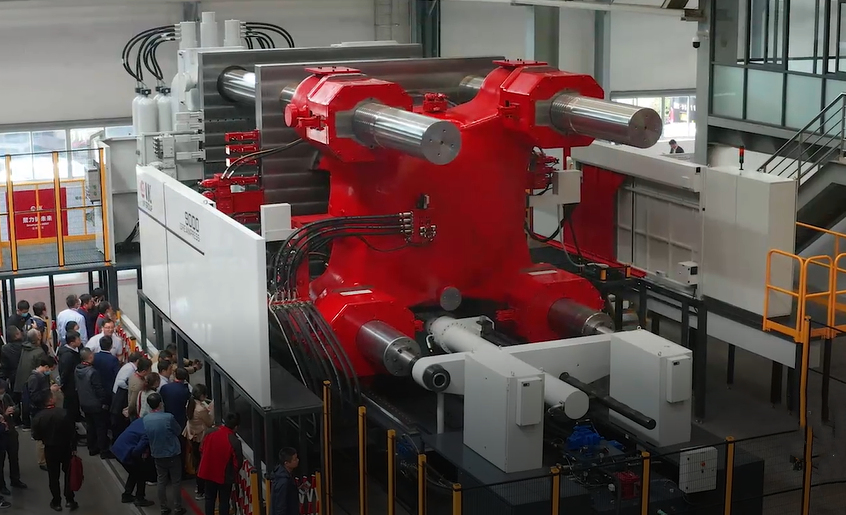

In addition, at the CCMT2024 exhibition held at the Shanghai New International Expo Center, Beijing Fanuc's sales of its main product numerical control system (CNC) officially exceeded the one million unit mark. This milestone event demonstrated Beijing Fanuc's success in The remarkable achievements in promoting the high-quality development of China's manufacturing industry further prove the development speed and widespread application of CNC machine tools in China2.

The development of CNC machine tools in China is not only reflected in the expansion of industrial scale and increase in market share, but also has made significant progress in technological innovation and product upgrades. For example, high speed and high precision have become important directions for the development of CNC machine tools. The continuous improvement of spindle speed, feed rate, calculation speed and tool changing speed all reflect the speed and level of technological progress of China's CNC machine tools3.

To sum up, the development speed of China's CNC machine tools is not only reflected in the expansion of industrial scale and increase in market share, but also in terms of technological innovation and product upgrading. It has made significant progress, showing China's competitiveness and competitiveness in this field. Market influence is growing.

The development speed of CNC machine tools in China is very rapid.

In recent years, the scale of China's CNC machine tool industry has continued to expand. It is expected that the scale of my country's CNC machine tool industry will reach 409 billion yuan in 2023, a year-on-year increase of 6.9%. This growth trend shows that China's CNC machine tool industry is developing very fast, and the market share of domestic high-end CNC machine tools has steadily increased, showing that China's competitiveness and market influence in this field are constantly increasing1.

In addition, at the CCMT2024 exhibition held at the Shanghai New International Expo Center, Beijing Fanuc's sales of its main product numerical control system (CNC) officially exceeded the one million unit mark. This milestone event demonstrated Beijing Fanuc's success in The remarkable achievements in promoting the high-quality development of China's manufacturing industry further prove the development speed and widespread application of CNC machine tools in China2.

The development of CNC machine tools in China is not only reflected in the expansion of industrial scale and increase in market share, but also has made significant progress in technological innovation and product upgrades. For example, high speed and high precision have become important directions for the development of CNC machine tools. The continuous improvement of spindle speed, feed rate, calculation speed and tool changing speed all reflect the speed and level of technological progress of China's CNC machine tools3.

To sum up, the development speed of China's CNC machine tools is not only reflected in the expansion of industrial scale and increase in market share, but also in terms of technological innovation and product upgrading. It has made significant progress, showing China's competitiveness and competitiveness in this field. Market influence is growing.

The precision of Chinese CNC machine tool processing is also constantly improving, which of course depends on the specific part design and processing requirements.

CNC machining can achieve high dimensional accuracy, often achieving tolerance requirements of ±0.01mm or less. This means that the dimensions of the machined parts are very close to those on the design drawings. In addition, CNC machining can also control the roughness of the part surface to meet specific requirements. Surface roughness of Ra 0.8μm or less can usually be achieved, and sometimes even below Ra 0.4μm.

Regarding the parallelism and perpendicularity requirements, CNC machining can ensure the parallelism and perpendicularity of the parts and ensure that the relationship between the various faces of the parts meets the requirements. Parallelism and perpendicularity requirements within 0.02mm can usually be achieved. In terms of aperture accuracy, CNC machining can achieve high-precision aperture processing, including drilling, reaming, etc., and can usually reach H7 level aperture accuracy, that is, the aperture is very close to the size required by the design.

However, actual accuracy requirements depend on specific part design and processing requirements. Different materials, shapes and processing methods may affect accuracy. In addition, factors such as machine tool performance, tool quality and processing environment also need to be taken into consideration1.

Despite this, China has made significant progress in the development of CNC machine tool technology. The development trends of CNC machine tools include high speed, high precision, compounding, intelligence, openness, parallel drive, network, extreme, and green. direction. The development of these technologies will further improve the accuracy and performance of CNC machine tools2.