About Us

CUSP is one of the leading CNC machining factory in China.We're your supplier for precision machining in aerospace, medical devices, green energy, auto parts, automation, and consumer electronics. We can support you a turnkey solution for you including design, molding, machining, surface treatment and logistics. CUSP specializes in precision CNC services for aluminum and magnesium die casting, CNC turning, CNC milling and Turn-mill compound machining etc. We have a variety of German, Japanese, and Chinese machining equipment that can provide 5-axis, 4-axis, and 3-axis precision machining.Total Solutions

CUSP expertise as a metalworking supplier is demonstrated in our turnkey solutions, which include feasibility studies, prototyping, material procurement, tool development, production processes, packaging, and logistics. These metalworking services can help you bring your products to market quickly and cost-effectively. Explore how CUSP can assist you with your next project.

Feasibility Study

Prototype Manufacturing

Material Procurement

Tooling Development

Production Process

Packaging and Logistics

Do you want to discuss a project with us?

Our support team is now ready to provide assistance! We always warmly welcome you to greet us.

Industries At CUSP, we are a precision metalworking company that manufactures and supplies high-tech components to global leaders in the Aerospace,auto parts,automation,green energy,medical equipment and consumer electronics.Our metal processing components are optimized for specific conditions in diverse industries, and we are ready to collaborate with you in shaping a better, more sustainable world.

Our Mission We strive for quality and technology, and specialize in the machining of difficult mechanical parts. As a precision metal machining supplier, CUSP uses the most advanced intelligent production line to manufacture parts faster, safer and more accurately than ever before, always providing customers with satisfactory products and services!

Aerospace

Aerospace Medical Equipment

Medical Equipment Green Energy

Green Energy Auto Parts

Auto Parts Automation

Automation Consumer Electronics

Consumer ElectronicsProcess Display

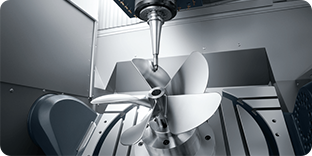

5-axis CNC machining features:*Machines with 3 linear axes (X axis, Y axis and Z axis) and 2 extra Swinging rotation axis for more flexible machining methods.

5-axis CNC machining features:*Machines with 3 linear axes (X axis, Y axis and Z axis) and 2 extra Swinging rotation axis for more flexible machining methods.*Extra Swinging rotation axis enables machining of wider areas in one setup.

*Specialized in space surface processing, irregular processing, hollow processing, Punching, oblique drilling, oblique cutting etc.

CNC milling machine processing features:*Strong adaptability to parts processing, able to process parts with complex or difficult-to-control dimensions

CNC milling machine processing features:*Strong adaptability to parts processing, able to process parts with complex or difficult-to-control dimensions*Able to process parts that need to be processed in multiple processes after one clamping and positioning

*High processing accuracy. The pulse equivalent of CNC devices is generally 0.001mm, and high-precision CNC systems can reach 0.1μm.

Automated CNC machining features:*CNC processing realizes automated operations, reduces manual operations and improves production efficiency.

Automated CNC machining features:*CNC processing realizes automated operations, reduces manual operations and improves production efficiency.*CNC automated processing has high precision, reaching the micron level, ensuring the quality and stability of workpieces. Not affected by human factors and avoid errors

*CNC automated processing has high reliability and can monitor and maintain machine tools through automated detection technology to ensure the stability and reliability of machine tools.

Shenzhen CUSP Precision Manufacturing Co., Ltd