Total Solutions

In the realm of industrial manufacturing, the metal processing industry encompasses critical processes like material forming, parts machining, and surface treatment. To meet the increasing demand for high-precision parts, modern metal processing leverages CNC (Computer Numerical Control) machine tools to overcome the complexities and precision challenges posed by traditional lathes and milling machines.

Feasibility Study

Prototype Manufacturing

Material Procurement

Tooling Development

Production Process

Packaging and Logistics

Feasibility Study

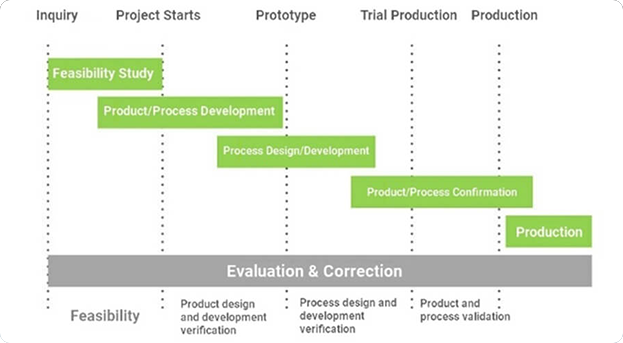

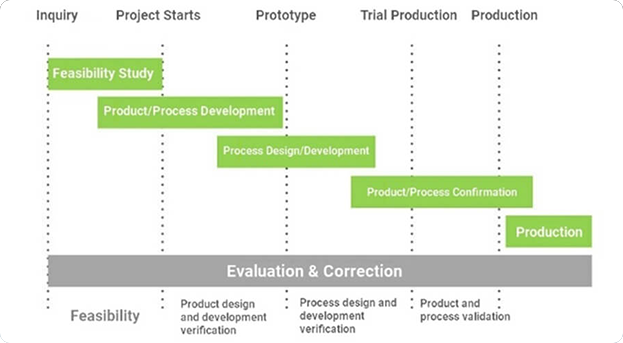

When customers send us a development inquiry, we will start a feasibility study in cross-functional communication before quotation. In consideration of mechanics of materials, machining accuracy, capacity loading, competitiveness, plant equipment, and any factor during production which may have an impact on the environment, with full communication in advance with customers, we will finalize to quote or not. Upon customers agreeing to the project,we will coordinate with the relevant departments to meet the customer's requests on specifications, quality, delivery date, packaging and logistics.

Prototype Manufacturing

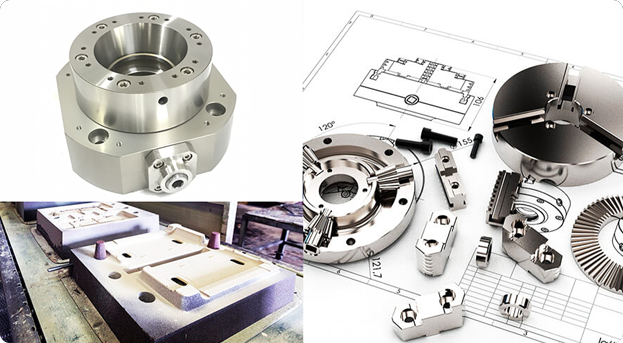

CUSP offers customized metal rapid prototyping services. We can make several prototype mockups without molding but use drawings and software design by a five-axis CNC machine. This prototype mock-up can be used for appearance and structure verification and shorten the development schedule in material development, product design, and customization. Under the digital manufacturing trend, applying digital technology can help us discover possible production problems in advance.

Material Procurement

Metal material is a general term of pure metal or alloy in industry. Common pure metal includes gold, silver, copper, iron, aluminum, tin, nickel, lead, zinc, carbon, etc. Combining two or more metal or non-metal is called alloy. Alloys can adjust the properties of pure metals to more industrially demanding characteristics. Common alloy is composed of iron and carbon as ferroalloys, including steel, stainless steel, carbon steel, tool steel and alloy steel, etc. Ferroalloy is also the most broadly used and most important material in engineering technology among metal materials. CUSP not only provides cast iron, stainless steel, carbon steel, but also non-ferrous metal forming technology, such as die-casting and extruding deformed aluminum alloy processing. In addition to above materials, we also accept customers designated materials for processing.

Do you want to discuss a project with us?

Our support team is now ready to provide assistance! We always warmly welcome you to greet us.

Tooling Development

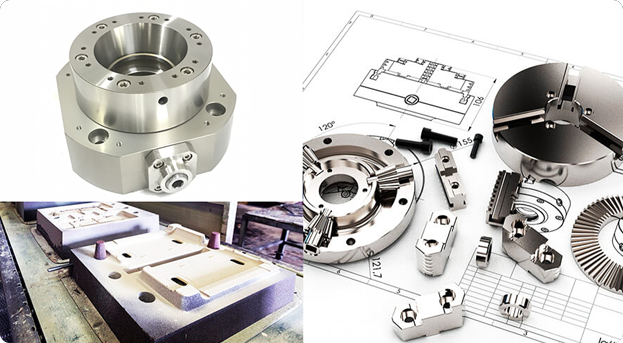

The forming of parts mainly goes through two different processes. The first process is to shape the metal material through a variety of molds, generally in rolling, casting, forging, extrusion, drawing, stamping, etc., and the tool for shaping the metal material is called a mold. The types of forming molds provided by CUSP are: extrusion molds, pressure casting molds, gravity casting molds, sand casting molds, hot and cold forging molds, stamping molds, etc. The second process of part forming is to use various tools to do milling, turning, boring, grinding, drilling, etc. on the initially formed workpiece or material block to remove material. In order to ensure that the workpiece can be fixed on the machine during the machining process, the workpiece must be fixed with a clamp. In addition, if the cutting tool meets a non-planar surface, in order to assist the accurate positioning of the tool, a jig will be used as an auxiliary tool for stable cutting. CUSP is a professional manufacturer of precision metal forming and parts machining. We have dedicated ourselves to developing various parts forming molds for many years, with a complete mods development procedure. In the stage of precision machining, standard operating procedure (SOP) such as quality verification, regular inspection and maintenance will be strictly implemented on development, testing and management of various jigs and fixtures.

Production Process

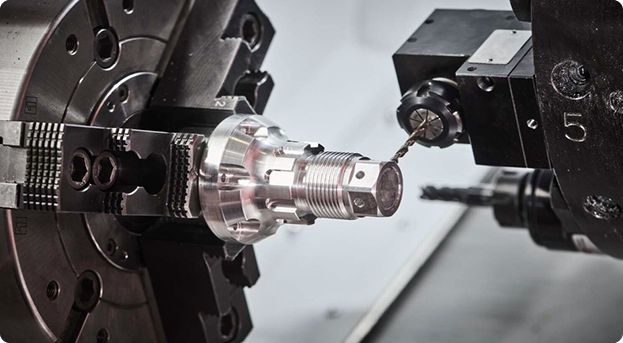

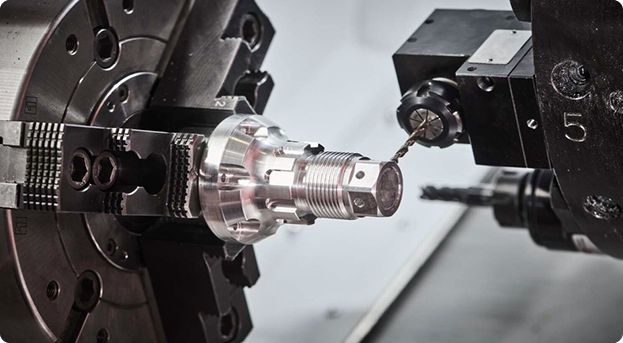

Precision Metal Machining, CNC Machining, Machining Process of Turning Machine and Milling Machine Metalworking is the process of shaping and reshaping metals to create parts, assemblies, and large scale structures. There are many kinds of modern metalworking processes, with professional and labor divisions. Mechanical tools are widely used in processes such as turning, milling, shaping, grinding, wire cutting and heat treatment, forging, casting, EDM, stamping, die casting, etc. CUSP has a total solution of precision machining, from metal material forming, machining, surface treatment, to functional testing, etc. We remove materials on metal workpieces, producing precision parts with tight tolerances and high surface quality. Converting precise 3D graphics to CNC programs through CAM to perform precision machining is the most widely accepted industrial model. We use CATIA CAD/CAM to simulate fixture clamping and cutting before actual machining, to confirm that all processes with accuracy and efficiency, improving the quality of the produced parts.

Packaging And Logistics

We plan appropriate packaging and logistics methods according to different finished products, materials, shapes, and customer regions. The last part of the precision machining solutions provided by CUSP is packaging and logistics. A good packaging can provide effective protection for the finished products. With logistics transportation by sea, air and land, the finished products can be delivered to the customers safely without errors. The finished parts manufactured by WKPT have the properties of high-mix, low-volume. According to the material and shape, the packaging methods are divided into different styles such as pallets, wooden boxes, and folding cages. The finished products are under rust-proof and protection at the packaging site, and marked and packaged according to the customer's instructions.

Q

How can we solve the poor surface quality of stamped parts?

A

Surface quality problems such as scratches and bumps may occur during the stamping process. The solution is to optimize the die design to reduce the contact area and friction, as well as to use suitable stamping lubricants to improve the surface quality.

Q

What is the role of heat treatment?

A

The function of heat treatment is to increase the hardness and strength of the mold and to remove internal stresses in order to increase the life of the mold.

Q

What factors determine the accuracy of a mold?

A

The precision of the mold is determined by processing precision, assembly precision, positioning precision and other factors.

Q

What are the tolerances for CNC machining?

A

Our standard machining tolerance is ISO 2768MK. tight tolerances of up to 0.002 can also be met.

Q

What are the benefits of CNC machining?

A

Accuracy and precision, speed and efficiency, cost-effectiveness, better capabilities and a wide range of compatible materials.

Q

What are the factors to consider before choosing a CNC material?

A

Hardness, mechanical properties, part function, dimensional tolerances, operating temperature, and cost.

Q

What are the types of CNC milling?

A

Face milling, flat milling, angle milling, form milling, profiling, row milling, side milling, milling slots or grooves, and drilling.

Q

What are the requirements of CNC engraving process for control system?

A

CNC engraving processing is first of all milling, so for the control system must have milling processing control ability, for small tool processing, and must provide feed-forward function, the path in advance of the speed reduction, to reduce the frequency of small tool cutter breakage, and to be in the more smooth path section to enhance the speed of the knife, so as to enhance the efficiency of engraving processing.

Q

Which materials are more suitable for engraving?

A

Metal materials suitable for engraving mainly include copper, aluminum, soft steel with hardness less than HR40, and non-metallic materials mainly include wood, resin, plexiglass and so on.

Q

How should we make adjustments to machining parameters when roughing conditions are bad?

A

Assuming that tool life is still not guaranteed at a reasonable spindle first speed, when adjusting the parameters, adjust the tool eating depth first, followed by the feed speed and then the lateral feed.

Shenzhen CUSP Precision Manufacturing Co., Ltd