Metal Forming

Metal Forming

Cast Iron Sand Casting

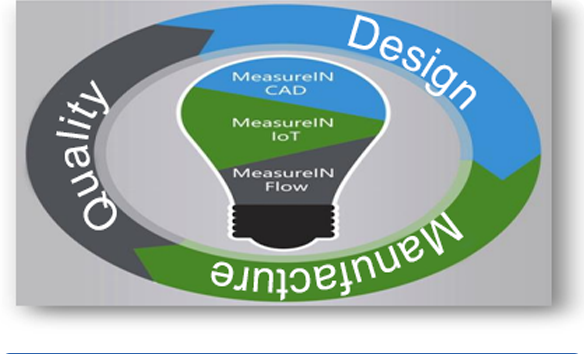

CUSP has an in-house casting system with capabilities in sand casting and mold flow analysis, providing various material iron casting services.

Aluminum Alloy Die Casting

With a cooperative system equipped with a 500-ton energy aluminum alloy die casting machine, we offer aluminum alloy die casting services.

Aluminum Alloy Gravity Casting

With a cooperative system for aluminum alloy gravity casting, we offer aluminum alloy gravity casting services for weights ranging from 5 to 100 kilograms.

investment casting

With a cooperative system for investment casting,we provide investment casting services for carbon steel, heat-resistant alloys, stainless steel, copper alloys, aluminum alloys, titanium alloys and ductile iron.

powder metallurgy

With a complete process system for powder metallurgy.we provide powder metallurgy services for iron alloy, copper alloy, stainless steel and other materials.

Aluminum Alloy Extrusion

With a cooperative system for aluminum alloy extrusion, we provide aluminum alloy extrusion molding services.